Clean protein provides a great start to young turkeys

By Hamlet Protein

Soybean meal (SBM) is the most commonly used protein source in animal diets and represents approximately two-thirds of total global output of protein feedstuffs. Normally recognized as a high-quality vegetable protein, SBM has a favorable amino acid (AA) profile containing all essential AAs necessary for animal growth and development.

To maximize growth potential in young turkeys, dietary protein requirements for poults up to 6 weeks of age can range between 24 and 28%. In order to achieve this crude protein target, dietary SBM inclusion levels can reach up to or beyond 50%, especially in all-vegetable based diets. Although these high SBM inclusions ensure amino acid requirements are satisfied, they can present other challenges to nutritionists (Leeson and Summers, 2009).

One concern when using high SBM inclusion levels is that any variation observed in nutrient content will have a greater effect on finished diet composition than low-inclusion ingredients. With this variation, challenges are presented where matrix values used in formulations may not accurately reflect the raw material leading to over- or under-formulating of SBM that can negatively affect poultry performance (Brown, 2021). Beyond nutrient variability, SBM at high inclusion levels can also contribute unwanted anti-nutritional factors (ANFs) that negatively affect the growth and development of poultry (Blanch, 2020ab).

To alleviate the negative effects associated with nutrient variation and soy ANFs in turkey starter diets, one nutritional strategy is to include enzyme-treated soy protein at the expense of SBM. Most procedures to further-process SBM pose the risk of heat damaging protein constituents which reduces the nutritional value of the ingredient. Hamlet Protein’s patented process successfully reduces the level of soy-ANFs without damaging the AA profile to provide a high-quality alternative protein ingredient. Though previous research shows the benefits of replacing a portion of dietary SBM with enzyme-treated soy protein to reduce the ANF content in finished diets for young broilers, there is limited research evaluating these types of products in young turkeys.

This article presents the results of an experimental trial with turkey poults fed diets supplemented with increasing dietary levels of enzyme-treated soy protein that was presented at the 2021 Annual Poultry Science Association Meeting (Brown et al., 2021). The objective of this trial was to evaluate the effect of increasing levels of enzyme-treated soy protein (ESP) on young turkey live performance through 42 days of age and determine optimal dietary inclusion rate using quadratic regression analysis.

Evaluation of enzyme-treated soy protein in young turkey diets

480 one-day-old female Nicholas Select poults were placed in battery pens and fed one of four dietary treatments: Treatment 1) corn-SBM + 0% ESP (control); Treatment 2) corn-SBM + 5% ESP; Treatment 3) corn-SBM + 10% ESP; Treatment 4) corn-SBM + 20% ESP. In each treatment ESP was increased at the expense of SBM. Poults were fed a two-phase feeding program consisting of a starter (0-21 days) and grower (21-42 days). Dietary treatments in each phase were formulated to be iso-caloric and contained similar amino acid ratios relative to digestible lysine and included an exogenous phytase and xylanase. Poults were orally vaccinated with a 1mL solution of coccidiosis vaccine at a 10x dose recommended by the manufacturer to present a mild challenge.

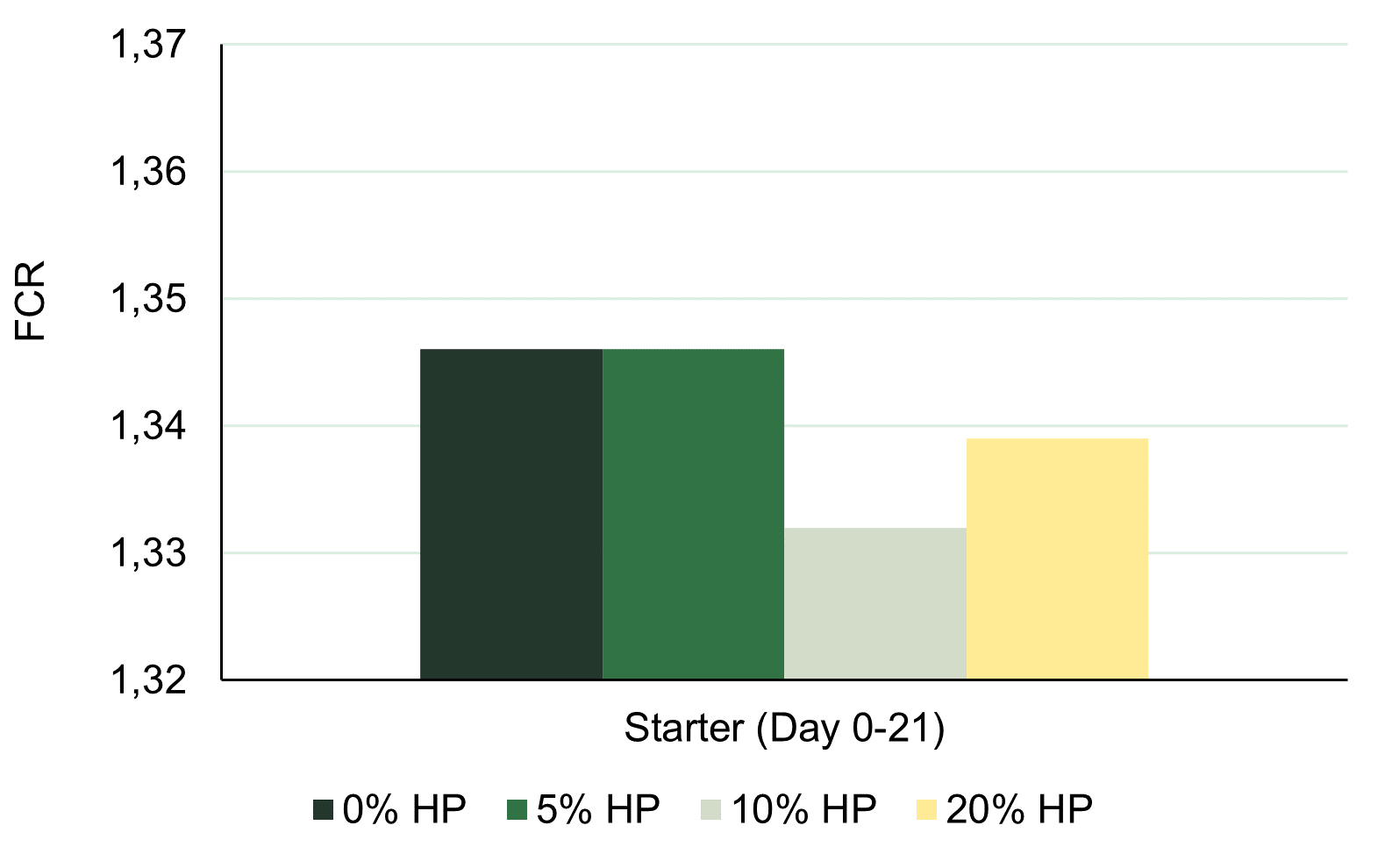

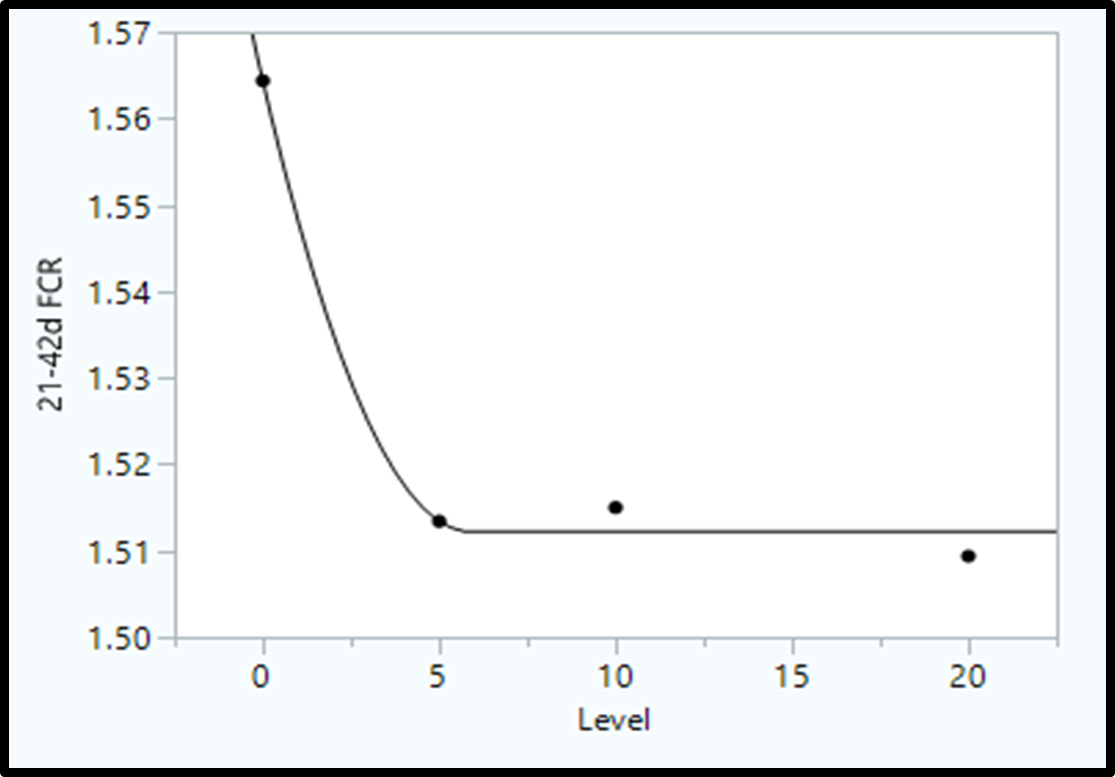

The inclusion of ESP to replace a portion of dietary SBM had a positive effect on young turkey growth performance during both the starter and grower phases. Though not statistically significant, the inclusion of ESP at 10% through 21 days led to a numerical reduction in starter FCR of approximately 1.5 points (Figure 1). When evaluating BW at 21 days, there was a numerical increase of approximately 2.00% when including 10% ESP compared to the corn-SBM control diet. Upon further evaluation, quadratic polynomial regression showed a near-significant trend (p=0.06) for BW at day 21 with a breakpoint at 9.91% ESP (Figure 2). During the grower phase, the inclusion of ESP improved feed conversion by approximately 5 points compared to the corn-SBM control diet regardless of inclusion rate. Further evaluation of grower FCR with quadratic broken-line regression showed a near-significant trend (p=0.09) with a breakpoint of 5.9% ESP (Figure 3). During both feeding phases, performance benefits of 10% ESP in the starter diet and approximately 6% ESP in the grower phase indicate SBM should be reduced to less than 40% inclusion in young turkey diets to alleviate the negative effects of soy-ANFs.

In conclusion, these data demonstrate the benefits of including ESP to replace a portion of SBM in young poult diets through 42 days of age. Considering all regression analysis, optimal dose of ESP is estimated to be approximately 10% during the starter phase (0-21 days) and approximately 6% during the grower phase (21-42 days).

Figure 1. Starter phase feed conversion ratio (FCR) of poults fed increasing levels of Hamlet Protein ESP (HP). Data with different labels represent significant difference (p≤0.05).

Figure 2. Quadratic polynomial analysis for day 21 body weight (BW) of poults fed increasing levels of Hamlet Protein ESP. p=0.06, breakpoint=9.91%

Figure 3. Quadratic broken line analysis for grower phase (day 21-42) feed conversion ratio (FCR) of poults fed increasing levels of Hamlet Protein ESP. p=0.09, breakpoint=5.90%