5 reasons why advanced soy proteins make a good choice in Calf Milk Replacer formulations

By Nicolas Anglade, Category Manager Ruminants, Hamlet Protein

A lot of people think that there is nothing better than milk protein for young calves, but high-quality vegetable protein can compete in Calf Milk Replacers (CMR) formulations. Our product HP 100 is an enzyme-treated soybean meal with a very low content of soy-derived Anti Nutritional Factors (ANF) currently used in young animal starter feeds as protein concentrate. In the young ruminant challenging preweaning phase, this vegetable protein specialty presents strong arguments to be integrated in the CMR ingredient list.

1. An excellent amino acid profile

It should be kept in mind that the digestion of the newborn ruminant is of monogastric type when we consider liquid feed (Milk, CMR). Indeed, thanks to the esophageal gutter which bypasses the rumen, the components of the liquid feed can escape ruminal fermentation and be digested in the abomasum and the intestine. Therefore, the amino acid balance of the liquid diet is fundamental, which is not the case when ruminal fermentation occurs and totally recombines the diet aminogram.

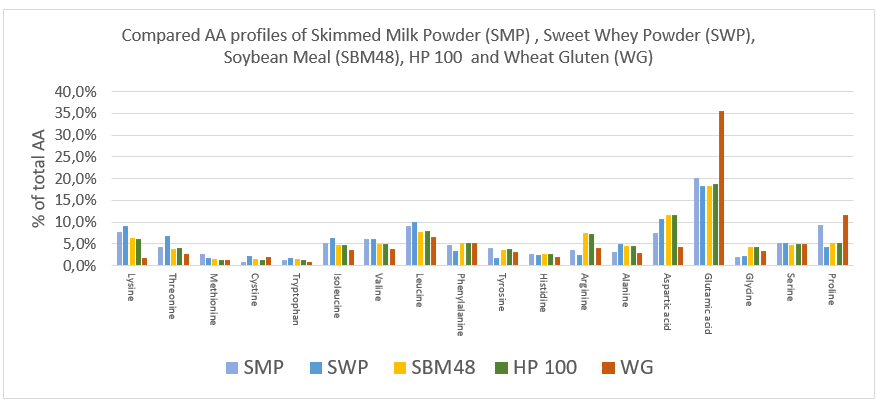

Milk proteins offer a typical Amino Acid (AA) profile that quite well suits young ruminants. Figure 1 compares typical dairy AA profile (from skimmed milk or dried whey) with vegetable AA profiles that can be included in CMR composition. We can observe that Soybean type profile (SBM 48, HP 100) sticks quite well to both dairy profiles. Wheat gluten is offering something different with a Glutamic Acid peak and low concentrations in Lysine. This amino acid profile of soy protein and, in particular, of HP 100 make it very suitable as an ingredient for use in milk replacers.

Figure 1 Amino acid (AA) profiles (% of total AA) of Skimmed Milk Powder (SMP), Sweet Whey Powder (SWP), Soybean Meal 48% CP (SBM48), HP 100 and Wheat Gluten (WG). Source: Feed tables.

2. Fast, clean and digestible protein

Newborn ruminants grow at a very rapid rate, gain muscle, develop organs and bones while their brain and nervous system also develop. This requires special attention to the protein in the diet. Thus, proteins integrated in CMR should be digested fast in the first part of the gastro-intestinal tract. If this absorption is only partial or too slow, the undigested proteins will be fermented by the microorganisms that populate the hindgut. The fermentation leads to the production of microbial biomass and associated gaseous emissions. This protein fermentation creates potential health and welfare disorders related to certain bacterial populations and painful problems of bloating or scouring, particularly for young animals not fully equipped at immunity level. The enzymatic process that converts soybean meal to HP 100 helps reducing the size of native soy proteins, making it easier and faster to digest. It works like a pre-digestion step. Furthermore, on a more environmental aspect, the improvement of the protein digestibility undoubtedly reduces nitrogenous effluents, and, by the way, contributes to a cleaner nutrition.

3. Competitive in formulation

Traditionally, most of the proteins provided in CMRs are of dairy origin. However, for 2 years, the cost of dairy ingredients has increased considerably and is prospected to remain at high levels. Indeed, the demand for milk products is stronger with population and life standards in constant progression but with a supply that is difficult to sustain (constraints on dairy farmers, climate change, energy costs, etc.). Economically, the protein point (the equivalent of 1% of protein in the formulation of 1 T of feed) has evolved between 80 and 120 € over the last 24 months if we refer to the international market for skimmed milk powder or whey protein concentrate. The consequences are huge for the formulation and pricing of CMRs and put pressure on both breeders of young ruminants and integrators. At the same time, the reference vegetable protein point, which is soybean meal, remained in a more reasonable price zone between €10 and €15 (GM and non-GM). Even if we have to consider that the protein point of Specialty Soy Proteins is a bit higher, their integration in CMR formulations remain very competitive and permit to maintain high protein levels in CMRs at a reasonable price.

4. A good start asks good gut health

As mentioned above, using soy proteins in the formulation of CMR’s presents significant benefits. But not just any soy! Indeed, conventional SBM contains anti-nutritional factors (ANF) that constitute a risk in the diet of young ruminants, especially at the gastro-intestinal level. The ANF triptych “allergens – trypsin inhibitors – oligo-saccharides” is a pitfall that the breeder, his nutritionist and feed formulator must circumvent. Soy ANF’s damage young animal digestion and gut health, and thus performance. At Hamlet Protein, the enzymatic treatment of SBM makes it possible to considerably reduce the ANF level which makes it safer to use in feed for young animals. The contribution to a healthy gut leads to improvements in overall animal status and efficiency, decreasing the amount of energy from feed being used for an immune response rather than growth.

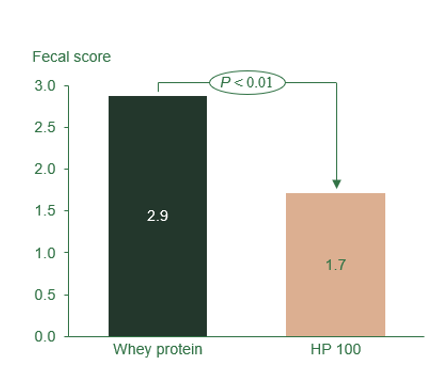

Interestingly, HP 100 significantly improved fecal score compared to WPC (Figure 2) in a trial done in 2019 at the University of Illinois, thus suggesting a lower incidence of scouring and cleaner calves when the inclusion rate of dairy protein in the CMR formulation was lowered.

Figure 2 Fecal scores of calves fed CMR based on whey protein concentrate (WPC) or where 50% of protein is replaced by HP 100. Fecal scores were assigned twice per day based on the following values: 1=normal, solid; 2 = semi-formed, pasty; 3=loose, stays on top of bedding; 4=watery, sifts through bedding.

5. Giving good trend to the growth curve

It is well known that the weaning of a young ruminant is conditioned by the weight gain of the animal during the preceding milk-feeding phase. It is traditional to consider a young dairy calf weaned when it has doubled its birth weight. The day-by-day growth is therefore fundamental to achieve this doubling as quickly as possible. In the trials carried out where milk proteins and the partial substitution of them with HP 100 have been compared, we have been able to find equivalent growth performance and feed conversion rate.

One of the main benefits observed in multiple trials is an earlier and greater consumption of starter dry feed offered beside the CMR with HP 100. This consumption of starter feed is also one of the elements that conditions safe weaning as we consider that the calf must be able to ingest dry starter-type feed beyond 2 kilos per day 3 days in a row. A good transition at weaning is key in both dairy heifer strategies and males fattening schemes. A supported ingestion of dry feed prepares the rumen in in the best possible way to take over from liquid feed and makes it possible to overcome the dip in growth at weaning feared by breeders of young ruminants.

We can therefore conclude that the integration of advanced soy proteins like HP 100 in the formulation of milk replacers has many advantages. The amino acid profile of HP 100 is very close to milk proteins with a significant price advantage. HP 100 is a clean vegetable protein because it is free of most anti-nutritional factors.

Events with Hamlet Protein

We attend events around the world. Meet us at exhibitions and seminars - we always look forward to welcoming you!

We also sponsor conferences with focus on young animal nutrition.

Have a look below where to meet us next.